Single Needle Bar Raschel Knitting Machines

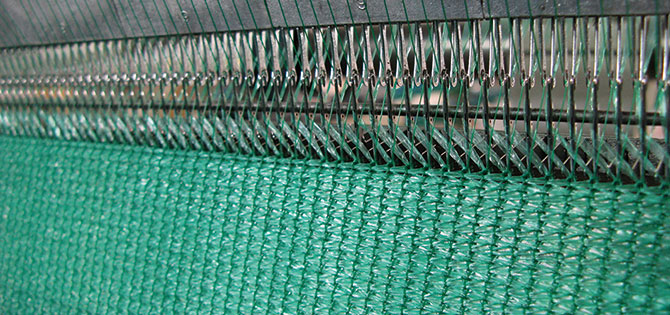

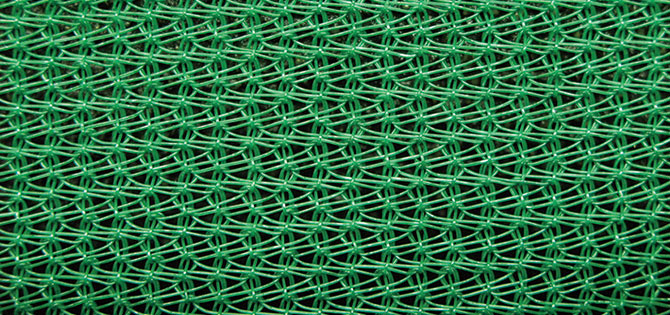

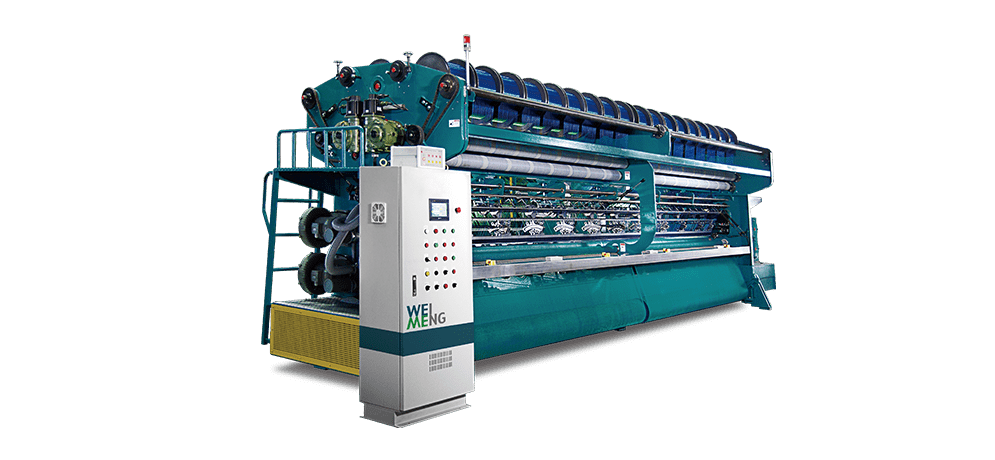

Our raschel knitting machines also knows as green net manufacturing machine is a high-quality, versatile machine that can be used to create a variety of nets for agricultural, construction, and sports use. With its rugged, distortion-proof welded steel construction and main drive by special cams, which are dynamically balanced and run in oil in the machine bed, our machine is built to last.

Main Applications

Our raschel knitting machines can be used to create a variety of nets for agricultural, construction, and sports use, such as:

Shade net: Our shade nets can be used to protect crops from the sun's harmful rays.

Greenhouse net: Our greenhouse nets can be used to create a controlled environment for growing plants.

Anti-birds & wind protection net: Our anti-birds and wind protection nets can be used to protect crops from birds and wind damage.

Building safety net: Our building safety nets can be used to protect workers from falls.

Scaffold net: Our scaffold nets can be used to protect workers from falls while working on scaffolds.

Industrial net: Our industrial nets can be used for a variety of purposes, such as protecting equipment and materials.

Football gate net: Our football gate nets can be used to protect players from injuries.

Packing net: Our packing nets can be used to pack a variety of products, such as potatoes, onions, and fruits.

Trusted shading net machine manufacturer

Provide the most reliable and most affordable shading Net Machine, Wei Meng is based on the rich manufacturing experience of raschel knitting machine, developed the highest quality green net manufacturing machine, and manufactured the shading Net Machine with the best shading effect. Wei Meng is your most trusted green net manufacturing machine manufacturer and supplier.

Green net manufacturing machine at affordable price

The green net manufacturing machine produced by Wei Meng not only produce excellent quality sunshade nets, but also have a wide range of applicable plastic materials. Most importantly, we provide high-quality shade Net Machine to China, India, Turkey, Manufacturers in Poland, Russia, and the Middle East at the most affordable low price.

- Rugged, distortion-proof welded steel construction.

- Main deive by special cams, which are dynamically balanced, and run in oil in the machine bed.

- Machines available for widely different applicants.

- Applications from fine mesh to coarse mesh available.

- Suitable for Round Yarn & Flat Yarn.

- Lower investment and high returns.

Nets for agricultural, construction and sports use, such as shade net, green house net, anti-birds & wind protection net, building safety nets, scaffold net, industrial net, football gate net & packing nets (for potato, onion, fruit) etc.

-

Applicable YarnHDPE Flat Yarn, Monofilaments, Polyester, Rayon, Nylon, TC, TR

-

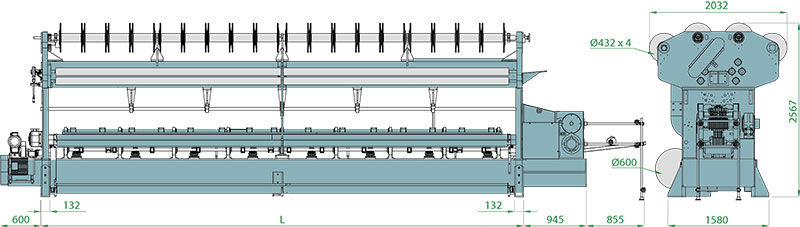

Working Width130" - 260"

-

Gauges2 - 18 needle per inch

-

Warp Supply SystemFrom: * Warping Beams / Creel Stand / Slitting Extension M / C

-

Performance300 - 600 rpm

-

Number of Bars2 - 8 Ground Bars (2 - 16 Pattern Bars Available)

-

Main Motor4.0 kw - 7.5 kw

-

Machine Weight4500 kgs - 9000 kgs

-